WASTE TREATMENT

VIDEOS

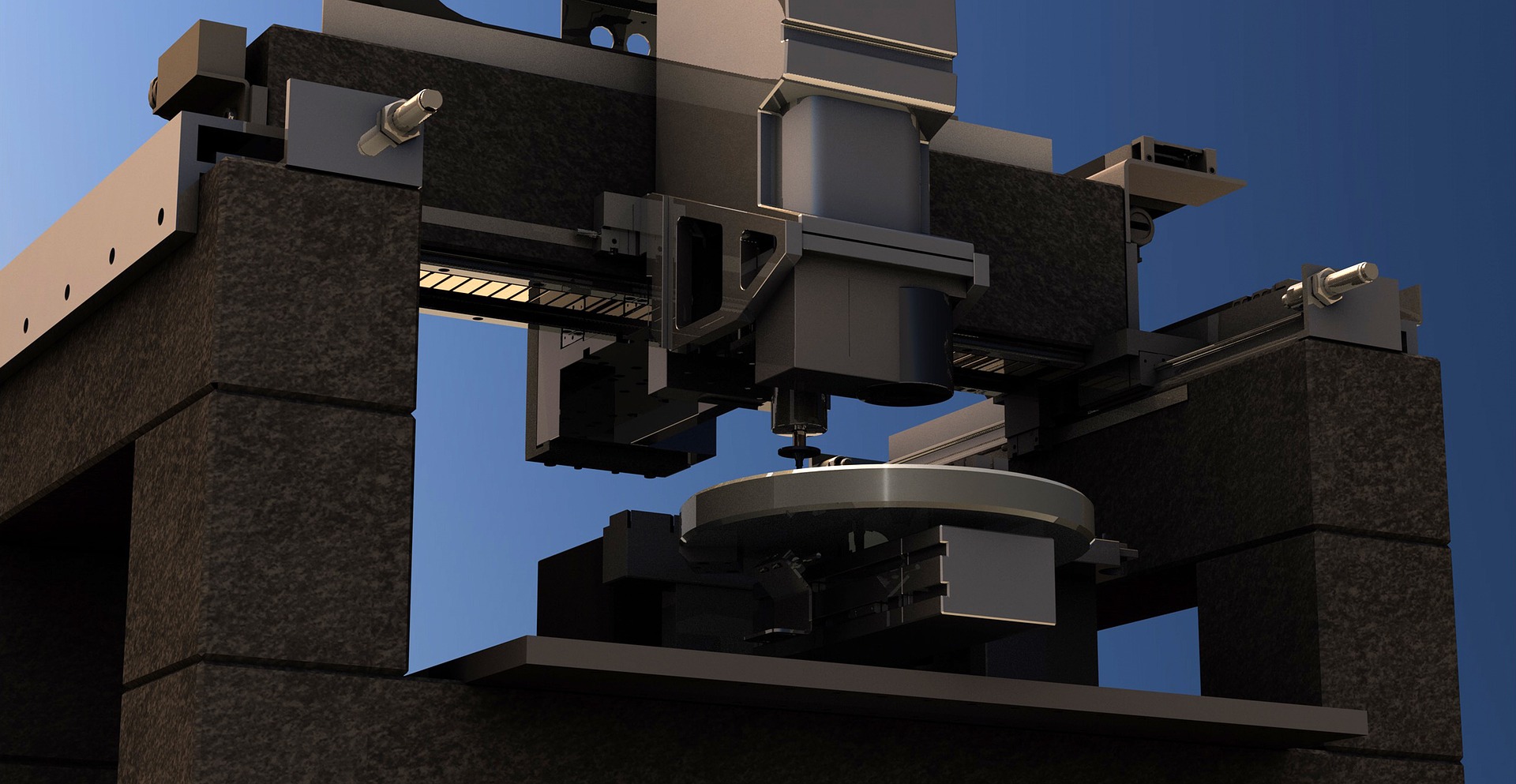

SEPARATOR HM 800

Intestinal and slaughterhouse waste processing

Hybag System Tutto: Whether food and preparation waste from the catering industry, industrial rejects, expired goods from large distributors, open and raw or packaged in plastic, tins or cans. Hybag Tutto, with its patented separation hammer mill, is the world's leading and proven unpacking and processing system.

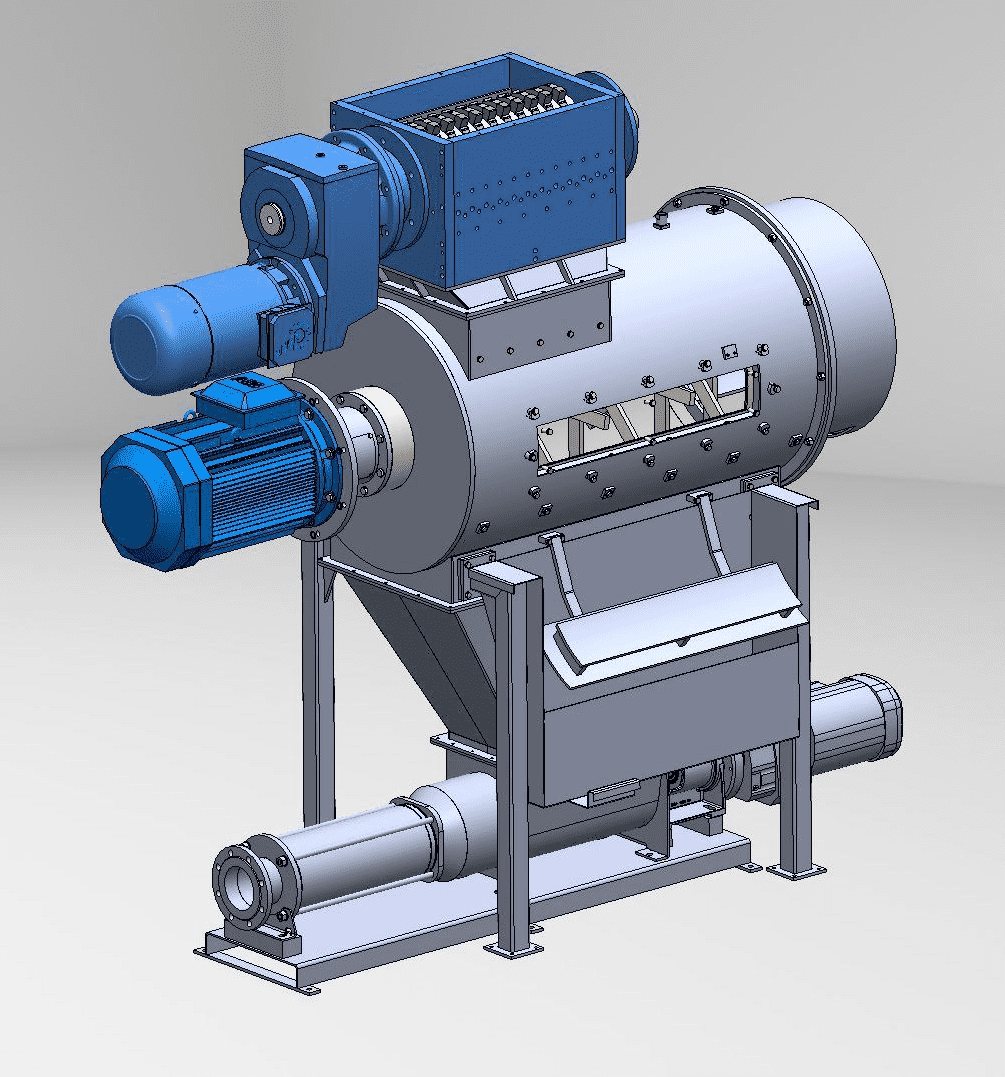

SYSTEM TUTTO

Food and preparation waste

Hybag System Tutto: Whether food and preparation waste from the catering industry, industrial rejects, expired goods from large distributors, open and raw or packaged in plastic, tins or cans. Hybag Tutto, with its patented separation hammer mill, is the world's leading and proven unpacking and processing system.

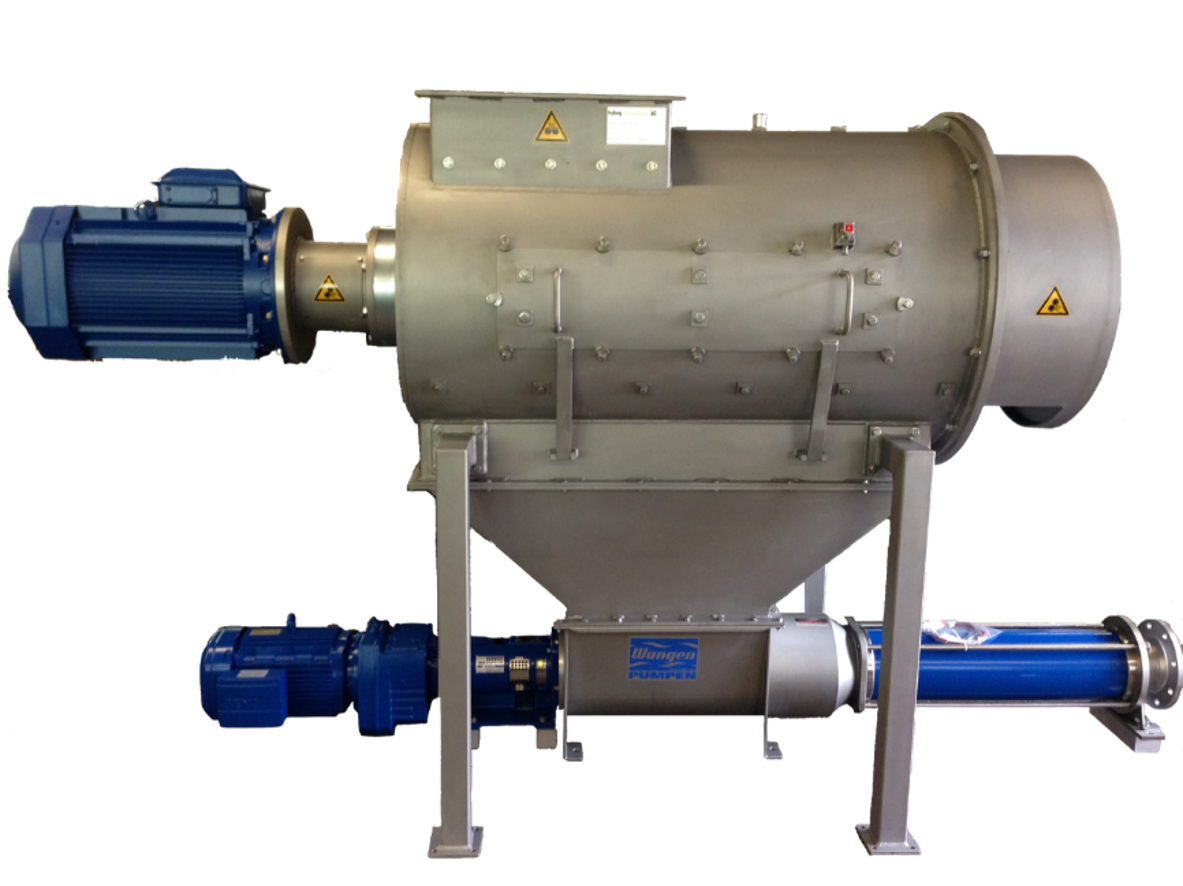

SYSTEM FILTRO

Screening waste in sewage treatment plants

Hybag System Filtro: Reduces incineration volume and costs by up to 90%, feeds the organic fraction into fermentation, increases gas yield accordingly while reducing CO2 emission

s.SYSTEM CASA

Organic recyclables from private households

Hybag System Casa: The increased collection of small and micro quantities in urban areas is most efficiently carried out using waste bags, as we know from household waste. Hybag Casa processes these bags at collection points and separates the recyclable substrate from packaging and foreign materials

.UNPACKING PRESS

Hybagunpacking press: For unpacking market waste in cans, tubes, tins or other packaging units. The packaging is burst open under high pressure and the contents are pressed out. The packaging materials are formed into a flat, round-shaped briquette and ejected. The substrate is fed into further processing via a pump system.

SEPARATOR TYP HM

Hybag separators are used worldwide to process large quantities of biogenic (compostable and fermentable) waste. It does not matter whether the waste is raw, cooked, unpackaged or packaged. Our separators shred the waste materials into particle sizes < 12 mm.

ULTRA-FINE-SEPARATOR

Hybag Separator:The Hybag UF Separator filters residual foreign matter particles out of the substrate.

The separator is preferably installed at the outlet of the fermentation process line. This system is particularly suitable if the substrate is subsequently spread on fields as fertiliser.

.CALIBRATOR

Single-shaft calibrator specially developed and adapted to Hybag hammer mill systems for the pre-crushing of organic recyclables from the food industry.

TIPPING SKIPS

Processing plant for market waste products

10 - 35m³ standard tipping skips or adapted to requirements

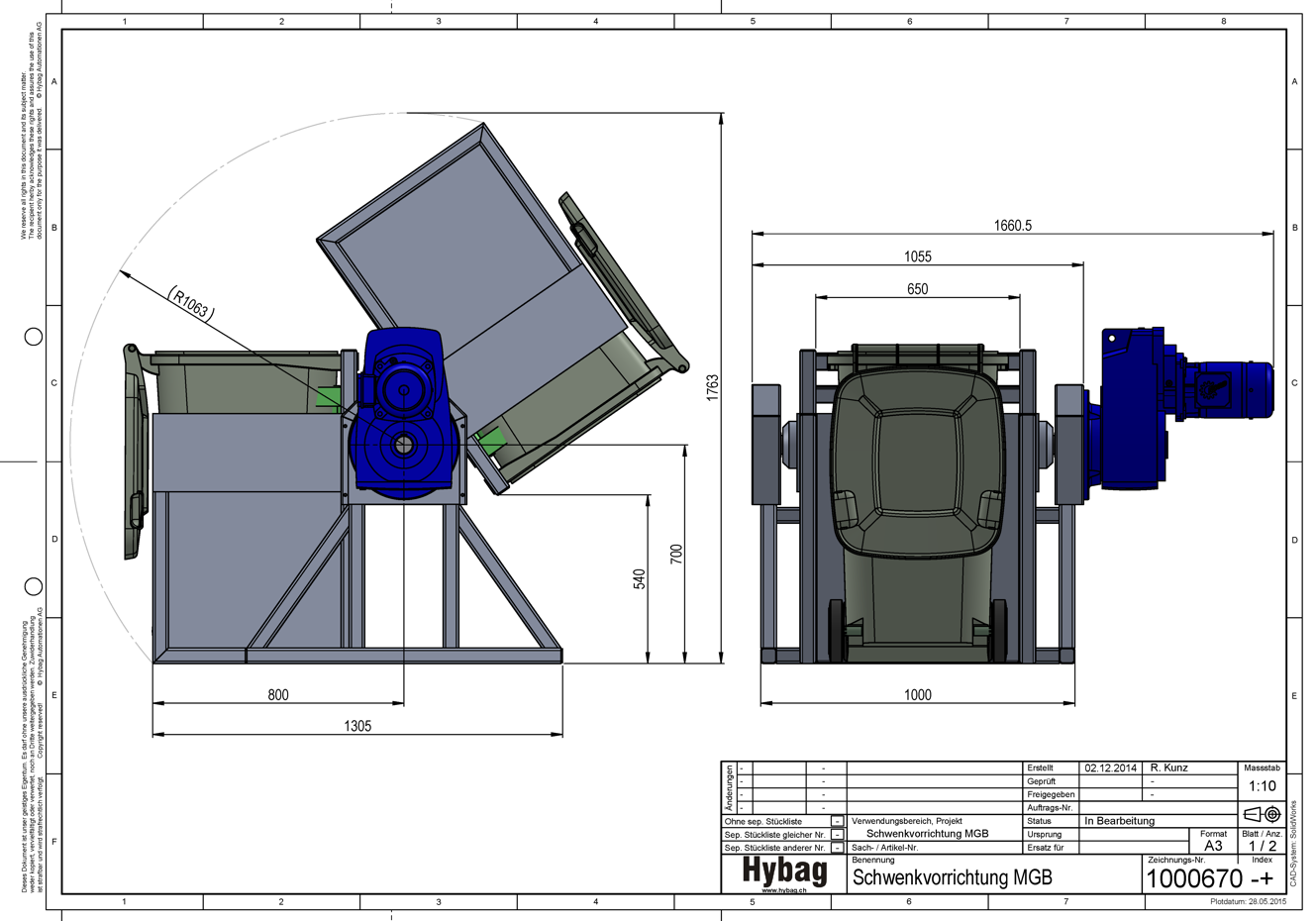

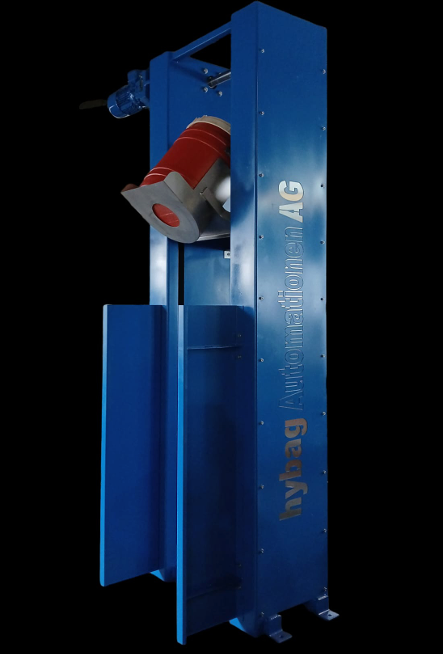

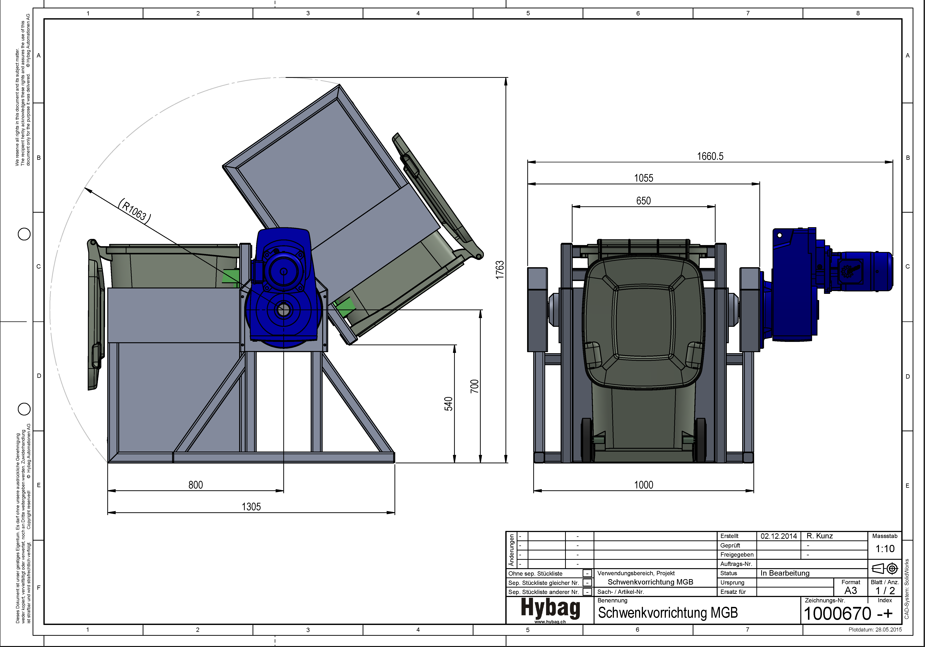

HUB-LIFTING & TIPPING DEVICES

In response to numerous customer requests, the Hybag team developed a compact, slim yet highly efficient lifting and tipping device for organic waste bins last year. For lifting and emptying MGB containers.

The space requirement is very low at 1.2 m². We are flexible in terms of height. Despite the typical Hybag quality and robust, durable design, the floor load is low at approx. 550 kg.

TILTING DEVICES SINGLE/DOUBLE

under construction

FUNNEL

under construction

TROUGHS WITH SPIRAL BOTTOMS

under construction

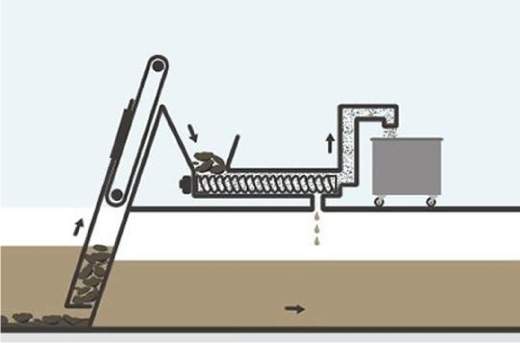

ASCENDING & DISRUPTIVE MATERIAL CONVEYOR

Conveying of recyclable materials using a screw conveyor: The conveyor element transports the organic recyclable materials into the patented Hybag Separations hammer mill. A radial fan with a capacity of 4,000 cm/h is located on the conveyor channel, which helps to increase the separation efficiency. The screw conveyor is driven by a gear motor with a frequency converter and is speed-controlled depending on the power consumption of the hammer mill motor. Conveyor element made of V2A stainless steel with sealed transitions, wear inserts made of Robalon RCH 1000 to reduce wear on the conveyor screw and safety transition piece to the hammer mill. Connection values: Gear motor 4.4 kW / radial fan with adjustment flap 1.1 kW