COMPANY PRESENTATION

.

Since 1973, the year Hybag Automationen AG, Linden was founded, Hybag has been involved in the development and manufacture of hydraulic drives and controls, processing plants for organic and other waste, and for separating, cleaning and pressing ecological recyclables.

In 2022, the company expanded and began collaborating with Oppliger FSA, Zäziwil, specialising in the separation and extraction of oil/water mixtures, emulsion separation systems, and the planning and implementation of aviation refuelling systems (see www.oppliger-fsa.ch).

STAFF

Managing Director: Patrick Oppliger

Administration/Finance: vacant

Production Manager: Thomas Michel

International Sales: Raimund Selz

Spare Parts Warehouse/Manure Removal: Roland Liechti

SYSTEM HYBAG TUTTO

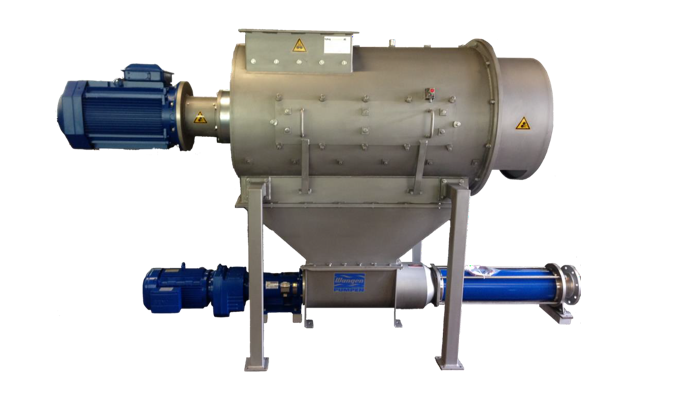

HYBAG SEPARATION HAMMER MILLS

NW 500 NW 600 NW 800

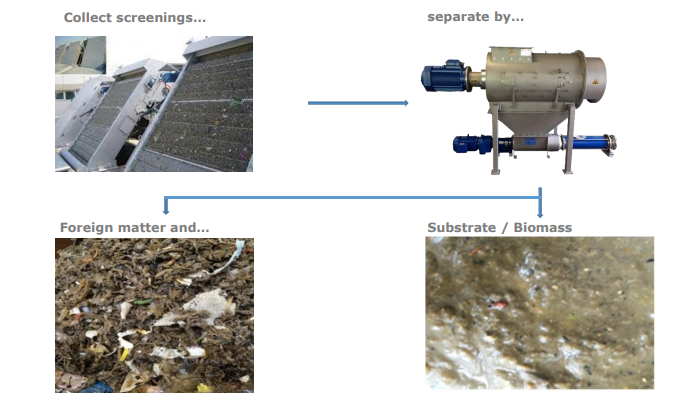

The Hybag separation hammer mill is used to process large quantities of biogenic

recyclables, whether raw, cooked, unpackaged or packaged.

The utilisation of biogenic recyclables in biogas plants usually requires not only

shredding to particle sizes < 12 mm, but also a high degree of removal of the impurities

contained therein. Hybag separation hammer mills achieve a particle size of 3-6 mm in the substrate.

The recyclable materials are crushed using the patented separation hammer mill and separated into biomass and foreign matter such as cutlery, plastic, sheet metal and other impurities.

A conveyor system pumps the homogeneous biomass into a storage tank. From there, the substrate (biomass) can be transported to further processing steps.

Our machine technology complies with composting standards and achieves a foreign matter content of < 1% in the substrate

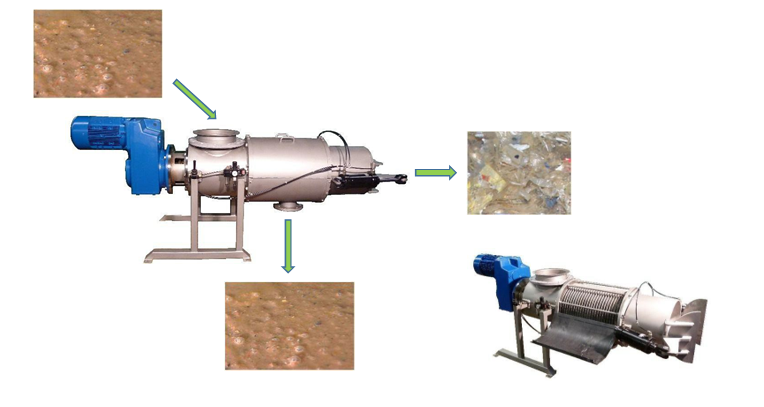

SYSTEM HYBAG FILTRO

HYBAG UNPACKING PRESS

HYBAG SCREW PRESS SEPARATOR

The Hybag screw press separator filters out impurities and residual particles from the substrate. The separator is preferably installed at the outlet of the fermentation process line. This system is particularly suitable if the substrate is subsequently spread on fields as fertiliser.

OUR CLIENTS

Disposal and recycling

For energy production, foodstuffs are unpacked prior to processing and foreign matter is separated from the biomass.

Food distributors

Transport damage, overstocking and expiry dates lead to waste

Catering

Food and vegetable waste accumulates in commercial kitchens and must be disposed of at great expense.

Agriculture

Bad weather, overstocking or incorrect storage and non-standard foodstuffs lead to waste

Food processing

Production residues, offcuts and faulty batches are recejts, i.e. waste

Waste water

Even washed-away material contains organic matter that can generate additional gas yield

OUR SERVICES

Economic success begins with careful planning...

Quantity analyses (economic efficiency)...

Location analyses (disposal routes)...

Placement analysis (floor plan design, engineering)...

Production and execution...

Assembly, commissioning and staff training...

Service and maintenance

SYSTEM FEATURES

… Environmentally friendly and resource-efficient

… Highly economical

… User-friendly

… Easy to maintain

… Modular components

… Low water and energy consumption

HYBAG TECHNOLOGY: PROVEN WORLDWIDE